Portfolio Artisan

We have produced thousands of high quality restorations, repairs and bespoke manufactured items over the years and have included just a select few below

illustrating our quality.

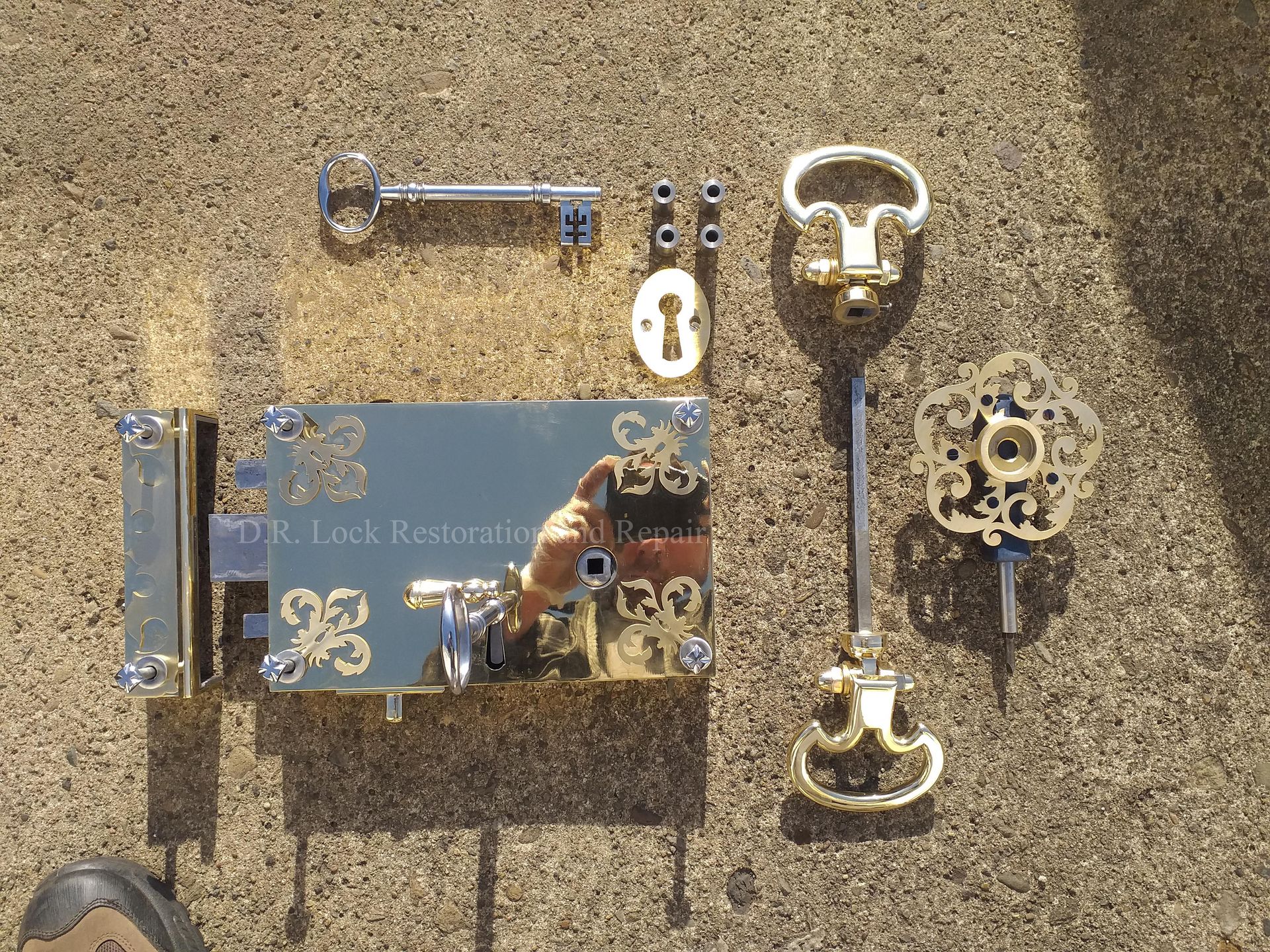

Below: Large full bespoke hand made Georgian period influenced Brass cased rim door lock 11" x 7" with 4" wide drop handles. All hardware, keys, drop handles and cut embellishments all hand made 1 off no castings used anywhere made from solid material brazed, welded and riveted where required.

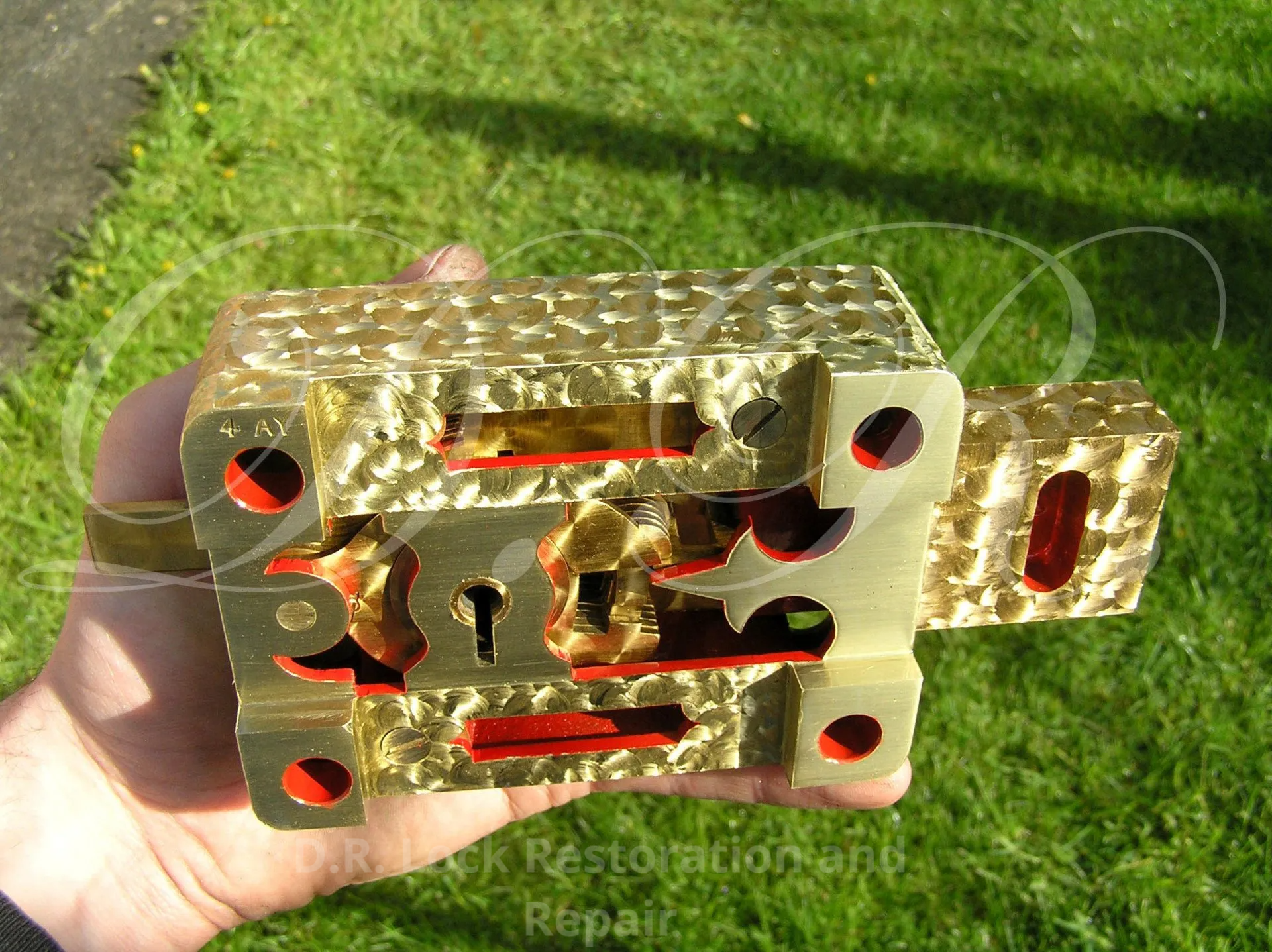

Below: Full bespoke hand made 7 lever furniture locks. No castings used or off the shelf parts.

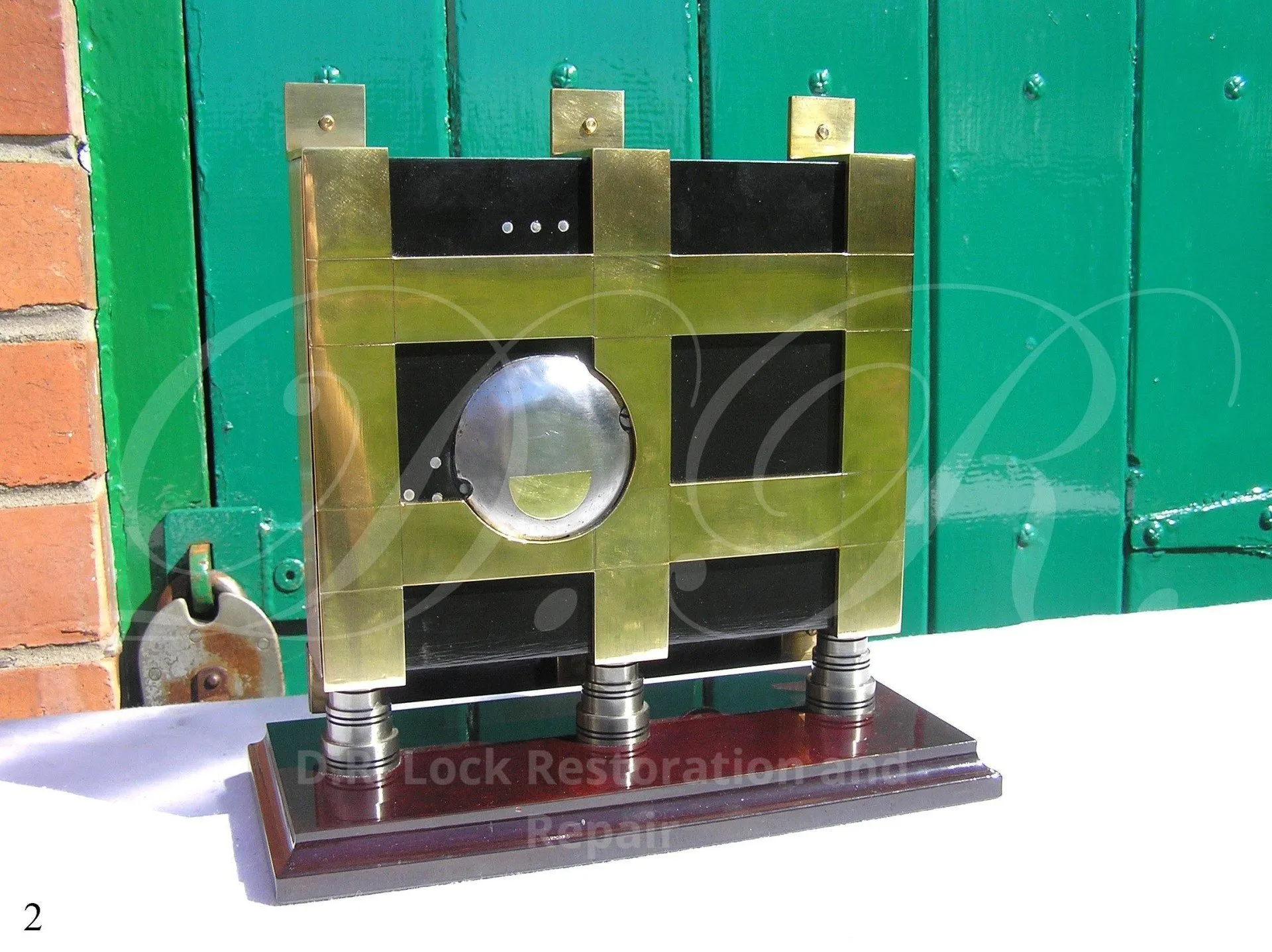

Below: A very special one-off Hobbs 1867 Parautoptic 6 slide Bank safe lock. Full bespoke manufacture of key which is changeable hence removable bits to change lock combination (permutation). Eagle Detector plate bespoke, rear Brass mount and plinth bespoke, cutaway and other associated display parts all bespoke. Based on the original Day & Newell 15 slide Parautoptic lock exhibited during 1851 Crystal

Palace Exhibition. The original 15 slide lock resides in South Kensington Science Museum, London SW7 2DD. Both locks significantly restored and all missing parts fully bespoke manufactured by my highly skilled master craftsman grandfather Tom Watson Certified Master Locksmith. All works to the 15 slide museum lock were carried out during the late 1960's when he worked for Chubb. The lock had many missing parts including the key and took around 9 months to

complete all works in his spare time. No other locksmith at the time was capable of the works carried out. This lock has over 150 moving parts and billions of possible combinations! Parautoptic (in Greek) means concealed from view. This lock was designed to be un-pickable and all measures were taken into its design and construction to defeat all the best techniques of the time. Even the very best safe engineers/lock picks today

would have a hard job attempting to unlock one of these without a key!

Below:

18th century influenced full bespoke hand made masterpiece key in Steel by proprietor

Danny BA TD (Hons). Photos below prior to polishing as it is still being worked on (April 2020). This key is made traditionally by hand tools including all the pierced work and mouldings. "Mouldings" or "Profiles" were formed by hand tools, not dressed up

castings. No CNC or any other fancy high tech modern machinery used. Only machine work in the form of lathe turned ball at top of the key and two ornaments inside the key, and cylinder for the base of bow. All traditional brazed construction in the fire, not welded.